[ad_1]

|

Hearken to this text |

A brand new design ensures excessive contact reliability with decrease insertion pressure

Connectivity is an intrinsic a part of at present’s industrial automation and robotic purposes. An ever-increasing variety of gadgets and peripherals rely upon steady connections to transmit energy and alerts to the printed circuit board (PCB). Managing these connections is labor-intensive, main many OEMs away from conventional screw terminals. Push-in terminal block PCB connectors supply simpler set up and tool-free meeting that may scale back the wiring workload by greater than 50%. Nonetheless, as automation programs change into extra advanced and labor shortages persist, engineers are in search of new methods to reinforce connector effectivity. This impressed Omron to take a recent have a look at their PCB connectors for alternatives to optimize. The result’s a brand new dual-spring construction that builds upon helpful options and minimizes the potential for missteps.

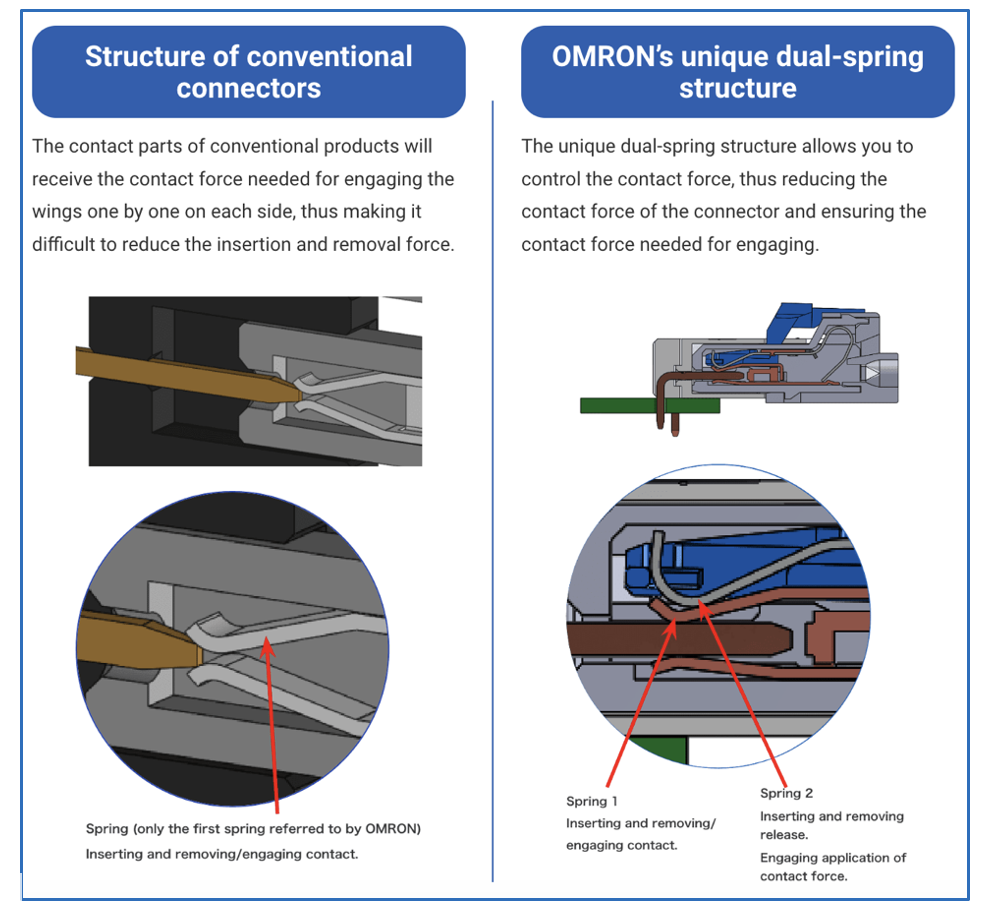

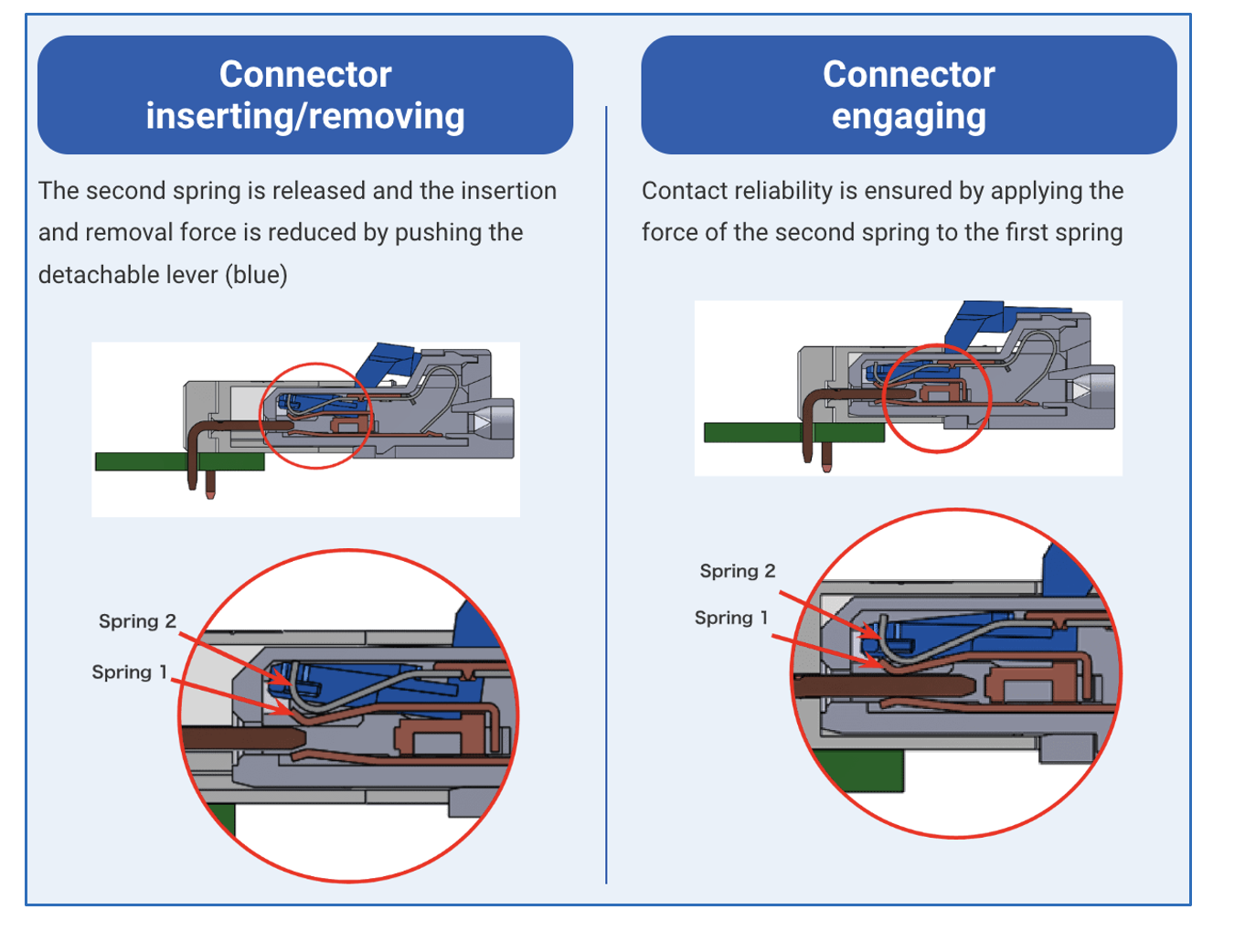

Typical connector construction vs. new dual-spring design

Typical push-in connectors have a single spring. Omron’s new PCB connector socket (XW4M) includes a second spring that, when related to the plug (XW4N), ensures contact reliability via the mixed contact pressure of each springs. The twin-spring design reduces the required insertion/removing pressure by way of a launch lever that opens the second spring when inserting and eradicating. By inserting the blue launch lever in the identical route because the connector deal with, the consumer can simply insert or take away the connector with one hand. (See video and diagrams under.)

Designed for ease of use within the area

Eliminates torque errors. Improper torque is without doubt one of the NEC’s most cited code violations. Whereas push-in connectors aren’t weak to over-torquing like screw terminal connectors, insufficient torque creates totally different issues. Unfastened connections have an effect on sign high quality, impedance mismatch, sign attenuation, and EMI/RFI ranges, in addition to posing the chance {of electrical} fireplace. The XW4N terminal connector eliminates the chance of improper torque. Wires are securely related by merely pushing them into the connector. No changes or particular instruments are crucial.

Prevents unintentional wire removing. The person launch buttons in typical PCB connectors are meant to simplify wire removing. As a result of the consumer should push and maintain the button with a screwdriver, it’s simple to press different buttons by chance. Omron changed launch buttons with holes designed to carry a slotted screwdriver in place, maintaining the consumer’s fingers free for cabling.

XW4M/XW4N push-in terminal block PCB connectors. (Courtesy of Omron)

Hurries up upkeep. Many commonplace connectors require eradicating the socket throughout upkeep checks. This takes extra time and will increase put on on the terminals. The discharge holes enable technicians to conduct continuity checks with out disconnecting the socket from the plug. This straightforward characteristic reduces time spent on upkeep and put on on account of repeated disconnections.

Be taught extra about Omron’s PCB terminal block connectors at XW4M/XW4N Push-in Terminal Block PCB Connectors.

[ad_2]

Source link