[ad_1]

Synthetic muscle mass are a progressing expertise that might at some point allow robots to perform like residing organisms. Such muscle mass open up new potentialities for a way robots can form the world round us; from assistive wearable gadgets that may redefine our bodily talents at previous age, to rescue robots that may navigate rubble searching for the lacking. However simply because synthetic muscle mass can have a powerful societal influence throughout use, doesn’t imply they’ve to depart a powerful environmental influence after use.

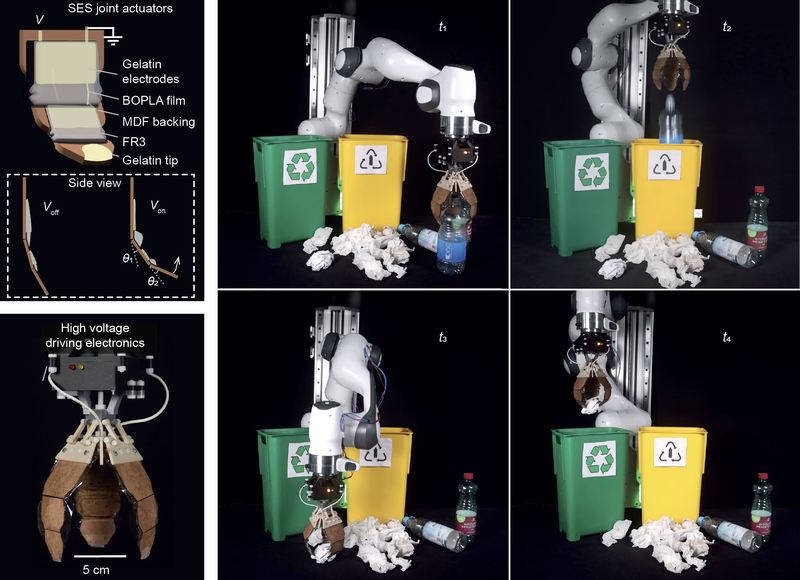

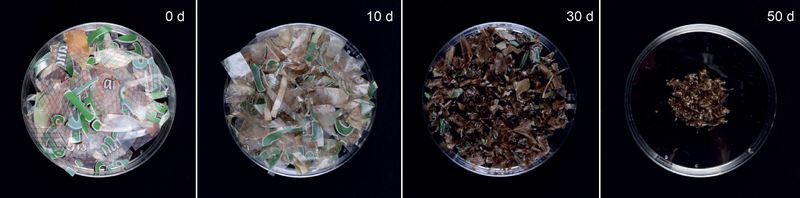

The subject of sustainability in tender robotics has been introduced into focus by a world staff of researchers from the Max Planck Institute for Clever Techniques (MPI-IS) in Stuttgart (Germany), the Johannes Kepler College (JKU) in Linz (Austria), and the College of Colorado (CU Boulder), Boulder (USA). The scientists collaborated to design a totally biodegradable, excessive efficiency synthetic muscle – based mostly on gelatin, oil, and bioplastics. They present the potential of this biodegradable expertise by utilizing it to animate a robotic gripper, which might be particularly helpful in single-use deployments equivalent to for waste assortment (watch the Youtube video). On the finish of life, these synthetic muscle mass might be disposed of in municipal compost bins; underneath monitored situations, they absolutely biodegrade inside six months.

We see an pressing want for sustainable supplies within the accelerating discipline of soppy robotics. Biodegradable components may provide a sustainable answer particularly for single-use functions, like for medical operations, search-and-rescue missions, and manipulation of hazardous substances. As an alternative of accumulating in landfills on the finish of product life, the robots of the longer term may grow to be compost for future plant development,” says Ellen Rumley, a visiting scientist from CU Boulder working within the Robotic Supplies Division at MPI-IS. Rumley is co-first creator of the paper “Biodegradable electrohydraulic actuators for sustainable soft robots”, printed in Science Advances.

Particularly, the staff of researchers constructed an electrically pushed synthetic muscle referred to as HASEL. In essence, HASELs are oil-filled plastic pouches which might be partially lined by a pair {of electrical} conductors referred to as electrodes. Making use of a excessive voltage throughout the electrode pair causes opposing costs to construct on them, producing a drive between them that pushes oil to an electrode-free area of the pouch. This oil migration causes the pouch to contract, very similar to an actual muscle. The important thing requirement for HASELs to deform is that the supplies making up the plastic pouch and oil are electrical insulators, which might maintain the excessive electrical stresses generated by the charged electrodes.

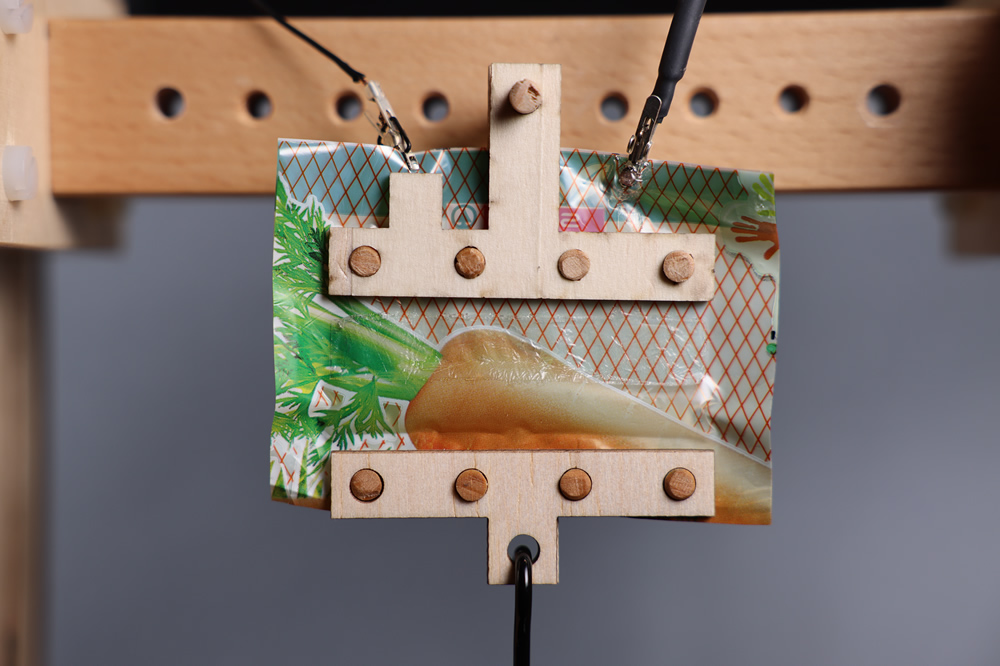

One of many challenges for this mission was to develop a conductive, tender, and absolutely biodegradable electrode. Researchers at Johannes Kepler College created a recipe based mostly on a combination of biopolymer gelatin and salts that may be instantly forged onto HASEL actuators. “It was essential for us to make electrodes appropriate for these high-performance functions, however with available parts and an accessible fabrication technique. Since our offered formulation might be simply built-in in numerous varieties of electrically pushed programs, it serves as a constructing block for future biodegradable functions,” states David Preninger, co-first creator for this mission and a scientist on the Comfortable Matter Physics Division at JKU.

The subsequent step was discovering appropriate biodegradable plastics. Engineers for this sort of supplies are primarily involved with properties like degradation price or mechanical energy, not with electrical insulation; a requirement for HASELs that function at a couple of thousand Volts. Nonetheless, some bioplastics confirmed good materials compatibility with gelatin electrodes and enough electrical insulation. HASELs constituted of one particular materials mixture had been even capable of face up to 100,000 actuation cycles at a number of thousand Volts with out indicators {of electrical} failure or loss in efficiency. These biodegradable synthetic muscle mass are electromechanically aggressive with their non-biodegradable counterparts; an thrilling outcome for selling sustainability in synthetic muscle expertise.

“By exhibiting the excellent efficiency of this new supplies system, we’re giving an incentive for the robotics neighborhood to think about biodegradable supplies as a viable materials choice for constructing robots”, Ellen Rumley continues. “The truth that we achieved such nice outcomes with bio-plastics hopefully additionally motivates different materials scientists to create new supplies with optimized electrical efficiency in thoughts.”

With inexperienced expertise turning into ever extra current, the staff’s analysis mission is a crucial step in direction of a paradigm shift in tender robotics. Utilizing biodegradable supplies for constructing synthetic muscle mass is only one step in direction of paving a future for sustainable robotic expertise.

Max Planck Institute for Clever Techniques

‘s purpose is to analyze and perceive the organizing rules of clever programs and the underlying perception-action-learning loop.

[ad_2]

Source link